#Modbus MQTT Device

Explore tagged Tumblr posts

Text

Arduino PLC | MQTT End Device | Industrial IoT device manufacturer | norvi.lk

How Programmable IoT Devices Operate

Having access to the most dependable and effective hardware speeds up the completion of your project. The ability to programme flexibly.

ESP32 Ethernet Device

When using ESP32 Ethernet, the NORVI ENET series is the best option because it has industrial-grade I/O and voltages. Both wireless and cable connectivity to the network are offered by ESP32 Ethernet.

Industrial Arduino Mega

The NORVI Arita is an enhanced version of the NORVI Series. Five conventional variants with a choice of two potent microprocessors are offered. Arita is built to deliver all of the micro-controller's performance while maintaining reliability. It works with practically all industrial input and output formats.

Arduino based Industrial Controller

Arduino IDE-programmable

Integrated OLED and customizable buttons for HMI

The ability to programme flexibly

LED signals for simple diagnosis

Applications Using a Programmable MQTT Device and Ultra Low Energy Batteries

Agent One Industrial Controllers are available for low power applications as well; STM32L series microcontroller-controlled devices are employed in ultra low power applications, where the devices must be powered by batteries for an extended period of time. When a device goes to sleep, the Agent One BT family is specifically built with transistor outputs to turn off external sensors.

Wall mount IoT Node

The NORVI SSN range is designed for independent installations in industrial settings with a focus on tracking sensor data or parameters from external devices. The implementations are made simple by the attachments for wall installation and pole mount.

NORVI Controllers

Our Address :

ICONIC DEVICES PVT LTD

Phone : +94 41 226 1776 Phone : +94 77 111 1776

E-mail : [email protected] / [email protected]

Web : www.icd.lk

Distributors

USA

Harnesses Motion LLC

1660 Bramble Rd. Tecumseh, MI

49286, United States

Phone : +1 (734) 347-9115

E-mail : [email protected]

EUROPE

CarTFT.com e.K.

Hauffstraße 7

72762 Reutlingen

Deutschland

Phone : +49 7121 3878264

E-mail : [email protected] MQTT End Device | Arduino PLC | Analog Input | Wireless sensor | ModBus MQTT gateway | Industrial IoT device manufacturer | WiFi Data logger

#Programmable IoT Devices#Industrial IoT Devices#Industrial Arduino#Arduino PLC#ESP32 Ethernet Device#Programmable Ethernet IoT Device#MQTT End Device#Industrial Arduino Mega#Arduino Mega PLC#Arduino based Industrial Controller#Programmable MQTT Device#Modbus MQTT Device#ESP32 Modbus device#Wall mount IoT Node#Wall mount sensor node#Programmable sensor node#Wireless sensor#Battery Powered IoT Node#Battery Powered Programmable Sensor node#Solar powered sensor node#MODBUS RTU ESP32#Modbus to IoT gateway#Modbus MQTT gateway#Programmable MQTT devices#MQTT over WIFI devices#MQTT over Ethernet devices#Industrial IoT device manufacturer#0 - 10V Arduino device#4 - 20mA Arduino device#ESP32 data logger

1 note

·

View note

Text

Discover the top 5 reasons why RS-485 IoT Gateways are essential for efficient and reliable industrial automation systems. Boost performance today!

#RS 485 IoT Gateway Solutions#Industrial IoT Gateway Solutions#industrial iot gateway devices#IOT gateway devices#IIoT gateway devices#MQTT IoT gateway#iot gateway manufacturers#Top IoT gateway companies#IoT gateway company#iot gateway solutions#modbus gateway#rs485 gateway#rs485 protocol#modbus rs485#modbus communication protocol#rs485 iot gateway#modbus protocol#iot gateway

0 notes

Text

What is an IoT gateway? The Definition, Function and Application

Introduction

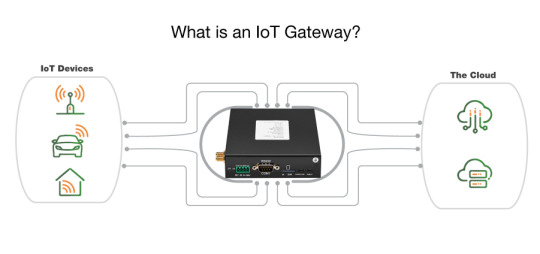

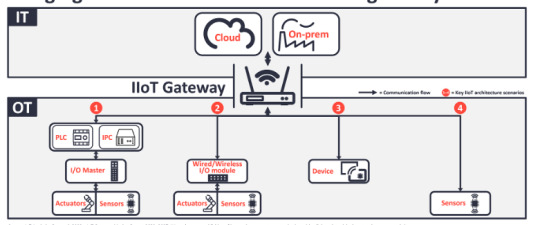

IoT gateway is essentially an intelligent central hub for IoT devices. An Internet of Things (IoT) gateway is a physical device or software program that acts as a connection point between the cloud and IoT devices such as controllers, sensors, and smart devices.

Organizations can use gateways to connect IoT devices for data processing and to monitor and manage IoT devices.

Why do you need to use industrial IoT gateways?

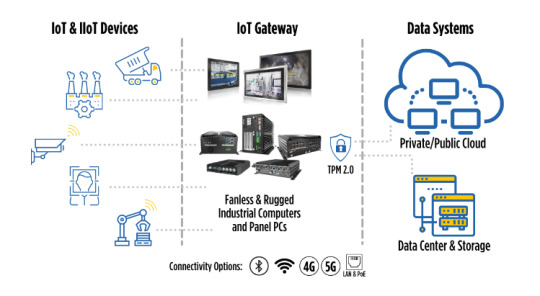

Almost all Industrial IoT solutions require gateways because small IoT devices such as sensors and actuators cannot connect directly to the IT infrastructure. Device limitations such as small physical size, harsh environmental conditions, remote locations, large battery power, fast response times, and low costs require suitable IoT device platforms, protocols, and networks to accommodate uses that are different from mainstream IT systems.

1. Protocol conversion – The main function of the gateway is to convert industrial system-specific protocols into business application languages: BACnet, Ethernet/IP, EtherCat, PROFINET and OPC UA

2. Edge Computing – Local applications running on the gateway interact directly with connected IoT devices, thereby improving response times, improving reliability, and reducing upstream bandwidth.

Features

1. Industrial IoT gateways wirelessly connect traditional and remote industrial equipment to next-generation smart infrastructure.

2. The Industrial IoT gateway is designed to be rugged and suitable for mission-critical systems and industrial environments that use sensor nodes or I/O devices to collect data.

3. IoT gateways can be configured with a variety of different protocols that enable them to communicate with these end-to-end sensor nodes or I/O devices.

4. Deploying an industrial IoT gateway can collect, filter, process and analyze data locally at the edge and then send it to the cloud. They relieve the burden on clouds and data centers from processing the vast amounts of data generated by sensors and industrial IoT devices, improving response times and reducing network transmission costs.

Finally, employing an IoT gateway to access previously hidden data from sensors, embedded controllers, and IO devices can be valuable for many enterprise processes and applications, such as:Remote monitoring, Maintenance,Production Optimization,Building Automation ect.

BLIIOT Industrial Edge IoT Gateway

Multi-serial ports and multi-network ports, downlink collection of multiple protocols, uplink compatible with multiple protocols, can collect data from 100 devices at the same time, and access multiple platforms at the same time. Applicable to Industrial Internet of Things, digital transformation, smart city, smart property, smart energy, smart transportation, etc.

#iot devices#smartcities#iot solutions#datacollection#awscloud#thingsboard#modbus#mqtt#edgecomputing

0 notes

Text

Enhancing AHU Performance with PLC-Based Control Systems

Imagine a world where your building breathes in oxygen. Where comfort meets air quality, and where energy is saved. It is the world where AHUs and PLC control systems are the starting point of everything in the domain of Energy management systems.

These AHU controllers (Air Handling Units) are the primary components of any new HVAC system. They serve as the lungs. But to make those lungs breathe better, smarter, and cleaner, you need a brain—enter the Programmable Logic Controllers (PLC).

We at Messung Industrial Automation are not just manufacturing PLC automation systems. We engineer intelligence. Smart PLC control is our ambition, and we aim to revolutionize the way AHU controllers operate, using a range of technologies, including Modbus, MQTT, compact PLCs, or IOT-enabled PLC.

What is a PLC-Based AHU Control System?

A PLC-based AHU control system is the ultimate HVAC master conductor. The flow, cooling, heating, and energy consumption of air are all controlled by real-time logic and precision through automation controllers.

Decision-making is the primary responsibility of a IoT enabled PLC (programmable logic controller), not just following instructions. Your AHU is designed to respond to data, adjust to changing surroundings, and function like a finely tuned machine with the help of intelligent controllers.

Whether it’s a mini PLC for a compact setup or a modular PLC for a multi-zone building, this IEC 61131-3 standard controller is the heartbeat of your air management system.

Core Functions of PLC Automation in AHU Controllers Applications

Sensor Integration

Temperature, humidity, CO2, and differential pressure are all sensors that your AHU controllers are equipped with. When it comes to Energy management systems, PLC control systems are necessary for reading, interpreting, and operating raw data.

Our intelligent PLCs work together with sensors to capture every detail of your indoor environment.

Data Analysis & Decision Making

After submitting the data, the PLC Automation magic begins. Our IEC 61131 based PLCs utilize advanced logic and maintain monitoring of variables such as:

Room occupancy

Outdoor air quality

Return air temperature

The intelligence in this scenario is not confined to automation alone it expands to the action of the PLC Control Systems.

Control Actions via Actuators

Now let's talk about the muscle of the operation. By utilizing PLC and Modbus TCP/IP, your automation controllers can dynamically control VFDs (Variable Frequency Drives) to regulate fan speeds while minimizing energy usage.

Actuated Dampers

Want zoned cooling in your building? Each damper is given precise guidance on when and where it should be opened or closed by our compact PLC, down to the second.

Valves

Our PLC automation system manages both hot and chilled water circuits, ensuring thermal comfort with accuracy.

Humidifiers & Dehumidifiers

System Overview: The NX-ERA JET Advantage

NX-ERA JET PLC is a digital command centre that is agile, adaptive, and always on alert as the AHU controllers. We have developed an intelligent and IEC 61131-3 standard PLC Control Systems that combine advanced logic, seamless connectivity, and flexible scalability. The NX-ERA JET is the key to ensuring that every component of your AHU system, including sensors and actuators, operates in perfect harmony.

Features of this IoT enabled PLC at a Glance

Modular PLC architecture is flexible and can be easily scaled for multi-zone management in large or changing infrastructure

The utilization of PLC with TCP/IP facilitates fast and secure communication between devices, including devices connected to remote systems

The integration of MODBUS RTU, Modbus TCP, and MQTT with BMS, SCADA, or cloud-based IoT platforms is facilitated by the native support provided by these protocols.

An integrated HMI that provides real-time, intuitive monitoring, diagnostics, and manual overrides.

Benefits of IoT enabled PLC for AHUs

In modern air handling, the focus isn’t just on moving air but moving it forward. Why? Integrating PLC control systems into AHUs can offer a transformative advantage in performance, sustainability, and adaptability for buildings. We should examine why PLC automation is the primary driving force behind intelligent HVAC solutions.

Improved Energy Efficiency

The value of energy is high, and PLC for energy systems with IEC 61131-3 standards optimizes every kilowatt. We can use our IoT enabled PLCs to save energy - up to 30% a time with intelligently controlled fan speeds, valve positions and damper angles that are real-time. Measurable reductions through these intelligent controllers help to reduce operational costs and greener footprints are not just numbers.

High Precision Control

AHU controllers equate performance with precision. Why? Our IEC 61131-3 compliant PLCs provide precise control over airflow, temperature and humidity. The result? Consistent comfort, efficient performance and strict environmental regulations.

Advanced Diagnostics

The use of intelligent PLCs with IoT systems means that problems can be prevented rather than delayed. With real-time monitoring and fault detection, teams can receive predictive maintenance insights to minimize downtime and maximize up time.

Scalability and Modularity

Our modular PLCs are designed to accommodate the growth of your building, offering compact systems and multi-zone installations. Do you require an immediate upgrade or expansion? These intelligent controllers can scale without complexity.

BMS Integration

Our PLC Control Systems with IEC 61131-3 standard integrates seamlessly with Building Management Systems, creating one intelligent ecosystem. Whether it’s HVAC, lighting, fire alarms, or access control—everything talks to everything for smoother operations.

In a world where data and efficiency are the primary drivers of change, PLC-controlled AHU controllers provide more than just automation; they also offer confidence. Our IoT enabled PLCs enable buildings to thrive rather than just functioning.

Intelligent PLC Control Systems for Smart Buildings

HMI with PLC Controllers - An HMI with PLC controller enables the observation of invisible areas. The entire package, including fan speed and filter life, is conveniently located at your fingertips.

MQTT based PLC and IoT Systems - The integration of IoT enabled PLC and MQTT support enables your AHU to communicate with the cloud, apps, and analytics platforms, simplifying the process of achieving predictive control and remote access.

Real-World Applications

Through PLC-based AHU control systems, we at Messung are changing the possibilities of environments from sterile labs to busy malls. With precision, adaptability, and unparalleled reliability, our intelligent automation controllers tackle the challenges associated with every application.

Pharma Cleanrooms - The precision of pharmaceutical products is essential in their application. The strict GMP standards are adhered to by our PLC control systems, which involve managing temperature, humidity, pressure differentials. The result? Zones that are sterile, upholding drug integrity and safety.

Commercial Buildings - Employee comfort drives efficiency. Our HVAC automation enables seamless climate management of all floors and departments. By utilizing intelligent design, efficient air circulation, and real-time monitoring, our IoT enabled PLCs enhance the productivity and satisfaction of customers in spaces.

Data Centers - Servers demand a stable climate 24/7. Even minor temperature fluctuations can compromise data. Our intelligent PLC Control Systems with IEC 61131-3 standard ensure uninterrupted cooling performance, reducing thermal risk and operational downtime.

Energy-Efficient Manufacturing - Today's manufacturers must strike a balance between sustainability and production. Without compromising comfort or compliance, our PLCs maximize AHU performance to reduce energy footprints, reduce emissions, and guarantee stable internal environments.

Wherever there's air to manage and performance to perfect, our Compact PLCs lead the way with intelligent control.

Messung’s Expertise in HVAC Automation

We at Messung lead the way in HVAC automation innovation for organizing smart air movement. Our legacy is created on trust, performance, and innovative control systems that transform indoor environments, not only on technology

Why Choose Messung PLC Automation?

We design smart automation systems rather than only selling PLC Control Systems. With more than four decades of engineering expertise, our PLCs are the favoured option of architects, MEP consultants, HVAC contractors, and facility managers across India and globally. Our internal R&D, field-tested dependability, and quick support system turn us into a progress partner rather than just a supplier.

Built on IEC 61131-3 Standard

To ensure every Messung programmable logic controller is consistent, dependable, and compatible with worldwide systems—today and tomorrow — our automation controllers follow this internationally recognized IEC 61131-3 standard.

Flexible Form Factors

Whether you are managing many air zones throughout a smart high-rise or automating a small rooftop AHU, our compact and modular PLCs meet every architectural and functional requirement.

Comfort, control, and conservation are not optional but rather vital in the quickly changing realm of smart infrastructure of today. Furthermore, realizing this potent triad calls for smart, adaptive control rather than just automation. That is what Messung's PLC-based AHU systems precisely provide. Our programmable logic controllers redefine air handling performance for buildings of all sizes with real-time responsiveness, easy BMS integration, IoT readiness, and IEC 61131-3 standard. Our intelligent controllers offer precision, dependability, and next-generation energy efficiency from sterile zones to skyscrapers. Should excellence be your goal, our IoT enabled PLC guarantees you lead rather than merely follow. Why settle for fundamentals when you may automate brilliance with our smart automation controllers?

FAQs

What makes a PLC suitable for AHU control?

Real-time processing, sensor compatibility, actuator control, and smooth BMS integration define good automation controllers. Messung's smart PLCs with IoT systems check every box

Can a modular PLC (Programmable logic controllers) handle multiple AHU zones?

Absolutely. Modular PLCs like Messung’s NX-ERA JET are great for big buildings since they can span levels and zones.

How does Messung's IoT enabled PLC enhance building performance?

Connecting to cloud systems and providing remote access help our IoT enabled PLCs to maximize energy efficiency and real-time maintenance cycles.

Why is Messung’s NX-ERA JET the ideal, affordable PLC choice for midscale operations compared to traditional compact or mini PLCs?

Messung’s NX-ERA JET offers advanced performance at an affordable price, making it perfect for midscale operations. It outperforms mini PLCs with better speed, scalability, and flexibility, without breaking the budget.

Are MQTT based Programmable logic controllers better than traditional protocols?

MQTT-based PLCs offer faster, lighter, and more effective communication than conventional systems like MODBUS RTU for remote and IoT-intensive applications.

#messing 1st blog ahu link#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#AHU controllers#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#AHU controllers systems#NX-ERA JET#HVAC solutions#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#Pharma Cleanrooms#Commercial Buildings#Data Centers#smart automation systems#programmable logic controller#BMS integration#smart PLCs#Modular PLCs

0 notes

Text

Integrating ARMxy SBC with InfluxDB for Time-Series Monitoring

In the world of Industrial IoT (IIoT), the ability to efficiently monitor, store, and analyze large volumes of time-stamped data is essential. From environmental sensors in smart factories to energy meters in power systems, time-series data forms the backbone of real-time insight and historical analysis.

InfluxDB, an open-source time-series database, is designed specifically for these use cases. Combined with the industrial-grade ARMxy Edge Gateway, it creates a robust edge solution for reliable data acquisition, storage, and visualization—all without depending on cloud availability.

🧠 Why InfluxDB on ARMxy?

InfluxDB is lightweight, high-performance, and optimized for time-series workloads. It supports powerful query languages, retention policies, and integrations with monitoring tools such as Grafana. When deployed directly on an ARMxy (RK3568J/RK3568B2) gateway, it becomes a local data engine with key advantages:

Minimal latency: Store and query data at the edge

Offline reliability: Operate without cloud or internet connection

Flexible integration: Compatible with Modbus, OPC UA, MQTT, and more

🏭 Real-World Use Case Example

Imagine a factory floor with multiple PLCs controlling machinery. Each PLC sends temperature, vibration, and power consumption data every few seconds. Instead of sending that data to a remote server, it can be ingested directly into InfluxDB running on the ARMxy device.

You can then use:

Telegraf for parsing and collecting metrics

Grafana for local visualization dashboards

Node-RED to add logic and alarms

The result? A self-contained edge monitoring system capable of showing trends, detecting anomalies, and buffering data even during connectivity drops.

🔗 Integration Workflow Overview

Install InfluxDB on ARMxy via Docker or native ARM64 package

Connect data sources: Modbus devices, MQTT brokers, etc.

Configure retention policies to manage local storage

Use Grafana (also installable on ARMxy) to build dashboards

(Optional) Forward selected metrics to cloud or central server for backup

✅ Benefits of Edge Time-Series Monitoring

Faster Insights: No need to wait for data to hit the cloud

Bandwidth Optimization: Only send essential data upstream

Improved System Resilience: Data remains accessible during downtime

Security & Compliance: Sensitive data can stay on-premises

🔚 Conclusion

Deploying InfluxDB on ARMxy Edge Gateways transforms traditional data loggers into intelligent local data hubs. With flexible integration options, support for real-time applications, and a compact industrial design, ARMxy with InfluxDB is a perfect fit for smart manufacturing, energy monitoring, and any IIoT scenario that demands fast, local decision-making.

Let the data stay close—and smart.

0 notes

Text

IoT Gateway: The Key to Efficient Water Monitoring Systems

In today’s world, where clean water is a pressing concern, monitoring water quality has become more important than ever. Whether it's for drinking, agriculture, or industrial use, ensuring safe water is essential. This is where the Internet of Things (IoT) plays a big role. Specifically, the IoT gateway acts as the backbone of any smart water quality monitoring system. But what makes it so important?

In this blog, we will explore the key role an IoT gateway plays in water quality monitoring. We will also understand how it connects different devices, handles data, and ensures efficient communication between sensors and cloud platforms.

What Is an IoT Gateway?

An IoT gateway is a device that connects IoT sensors and devices to the cloud or a central server. It collects data from different sensors, filters it, and sends it to a platform for analysis. Think of it as a bridge that enables communication between the devices on the ground and the software that processes data.

For water quality monitoring, this means receiving signals from sensors that detect pH levels, temperature, turbidity, dissolved oxygen, and other parameters. Without an IoT gateway, it would be difficult to gather all this information in real-time.

Why Is IoT Gateway Crucial for Water Quality Monitoring?

1. Real-Time Data Collection and Transmission

Water quality can change quickly due to weather conditions, pollution, or human activity. An IoT gateway helps in collecting data from various sensors in real-time. This allows authorities or businesses to act quickly if there's any issue with water safety.

2. Device Compatibility and Integration

Different sensors from different manufacturers can be used in one system. An IoT gateway ensures all these devices work together smoothly. It supports multiple protocols like MQTT, Modbus, and HTTP, making integration easier.

3. Data Preprocessing

Raw data from sensors might not always be usable directly. The IoT gateway filters and processes this data before sending it to the cloud. This reduces the load on cloud servers and improves response time.

4. Reliable Connectivity

Many water sources are located in remote or rural areas where network coverage is weak. A good IoT gateway can store data locally during connectivity loss and forward it once the network is restored.

5. Enhanced Security

Water quality monitoring involves critical data. IoT gateways come with built-in encryption and firewall settings to protect data from unauthorized access or cyber threats.

Application of IoT Gateway in Real-World Water Systems

IoT gateways are now widely used in various water-related projects. For example:

Urban Water Supply: Ensures the water reaching households is safe to use.

Agriculture: Monitors water quality in irrigation systems to avoid crop damage.

Industrial Use: Keeps a check on water discharged from factories to avoid environmental pollution.

IoT Tank Level Monitoring: IoT gateways help in reading the water level and quality data from tanks and storing it securely.

Integration with Industrial IoT Systems

In many industries, water is used in production processes, cooling, and cleaning. Monitoring water quality here is crucial. The industrial IoT setup often includes several machines and sensors working together. The IoT gateway collects data from all these points and ensures that everything is operating within safe limits.

This not only improves operational efficiency but also helps in meeting regulatory standards and avoiding fines.

Role in IoT Device Monitoring

The IoT gateway doesn’t just connect sensors. It also plays a major part in IoT device monitoring. It keeps track of the status of each device, ensures they are working properly, and sends alerts if any device stops functioning. This makes system maintenance easier and prevents long downtimes.

For example, if a pH sensor stops sending data, the gateway can trigger an alert immediately, so it can be fixed before the problem spreads.

Remote Monitoring and Management

One of the biggest advantages of using an IoT remote monitoring solution is that it allows you to manage water systems from anywhere. The IoT gateway makes this possible by continuously sending data to the cloud. Users can then log in through a dashboard or app and view real-time water quality reports.

This is especially useful in large areas like cities or agricultural fields, where visiting each site manually would take too much time.

Efficient IoT Device Management

With so many sensors and devices involved, managing them can be a big task. This is where IoT device management becomes important. Through the gateway, users can update firmware, restart devices, or reconfigure settings remotely. This saves time and reduces the cost of manual maintenance.

It also allows businesses to scale their operations. For example, if a water treatment company wants to expand to new locations, they can simply add more sensors and configure them through the same system.

Challenges and Considerations

While the benefits are clear, there are some challenges in using IoT gateways for water quality monitoring:

Initial Cost: High-quality gateways can be expensive, especially for small businesses.

Power Supply: In remote areas, ensuring a continuous power supply can be tricky.

Data Overload: Without proper filtering, too much data can slow down the system.

Technical Knowledge: Setting up and maintaining an IoT system needs skilled professionals.

However, with proper planning and support, these challenges can be managed.

Future of Water Quality Monitoring with IoT Gateways

As more people become aware of the importance of clean water, the demand for smart monitoring systems will grow. IoT gateways will play a bigger role in automating tasks, improving response times, and providing accurate data for better decisions.

We can expect to see:

More solar-powered gateways for remote areas

AI-based data analysis linked through the gateway

Better integration with mobile apps for user-friendly access

Final Thoughts

Water is one of our most valuable resources, and protecting it should be a priority. Using an IoT gateway in water quality monitoring ensures that we get accurate, real-time data to make better decisions. Whether it’s for cities, farms, or industries, IoT gateways provide the foundation for smarter, safer water systems.

They also support a range of technologies such as IoT tank level monitoring, industrial IoT, IoT device monitoring, IoT remote monitoring solutions, and IoT device management, making them an all-in-one solution for modern water systems.

By adopting IoT gateway technology, we take one big step towards sustainable water management and a healthier future.

0 notes

Text

Step Into the Future: Learn IIoT and Industry 4.0 at Just Engineering

The world of engineering is undergoing a revolutionary transformation. From traditional manufacturing to smart factories, the future is driven by Industry 4.0 and the Industrial Internet of Things (IIoT). These technologies are changing the way factories operate—making them smarter, faster, and more efficient.

To stay ahead in this digital era, engineers need to move beyond textbooks and embrace the technologies shaping tomorrow. That’s exactly what Just Engineering, Pune, empowers you to do.

🔍 What Are Industry 4.0 and IIoT?

Industry 4.0 marks the fourth industrial revolution, combining automation, data exchange, and smart technologies like AI, robotics, and cloud computing.

IIoT (Industrial Internet of Things) connects machines, sensors, and devices in a factory to collect and share data in real time.

Together, they are the backbone of smart manufacturing—enabling predictive maintenance, real-time monitoring, and autonomous decision-making.

🎓 Why Learn These Technologies at Just Engineering?

Just Engineering, in collaboration with SAGE Automation, Australia, offers industry-focused, hands-on training that prepares you for the real-world demands of IIoT and Industry 4.0.

What You’ll Learn:

PLC and SCADA programming and integration

IoT-enabled automation using real industrial hardware

Sensor networks, data logging, and analytics

Connectivity protocols like MQTT and Modbus

Smart factory simulations with robotics and process control systems

This practical training transforms your resume from theory-based to industry-ready.

🌍 Your Career, Globally Ready

Engineers trained in IIoT and Industry 4.0 are in demand across industries—automotive, manufacturing, energy, logistics, and more. With Just Engineering’s globally aligned training, you can tap into:

High-paying automation roles in India and abroad

Future-forward positions like IIoT Architect, Automation Specialist, and Controls Engineer

Job opportunities in companies embracing smart factory transformation

🚀 Final Thought

The future belongs to engineers who can think digitally and work with intelligent systems. By learning IIoT and Industry 4.0 at Just Engineering, you’re not just learning—you’re stepping into a future that’s already here.

0 notes

Text

Industrial IoT Gateway: Empowering the Future of Industry with Creative Micro Systems

The rise of the Industrial Internet of Things (IIoT) has paved the way for smart factories, connected equipment, and data-driven decision-making across various industries. As businesses seek to harness the power of real-time data, the need for effective, reliable, and secure solutions has never been more crucial. At the heart of this transformation lies the Industrial IoT Gateway, a pivotal technology that connects industrial devices to cloud systems and ensures seamless data flow. Creative Micro Systems is leading the charge in providing advanced Industrial IoT Gateway solutions that unlock the true potential of IIoT.

What is an Industrial IoT Gateway?

An Industrial IoT Gateway acts as an intermediary device that connects physical industrial machines and sensors to cloud platforms or enterprise systems. It gathers data from these devices, processes it locally (at the edge), and either sends relevant insights to the cloud for further analysis or makes real-time decisions on-site. Unlike traditional systems, which rely on sending all data to the cloud, IoT gateways enable localized processing, which reduces latency, conserves bandwidth, and ensures faster decision-making.

The gateway serves multiple purposes: it converts data from various industrial protocols into a standardized format, provides a secure connection for data transmission, and ensures real-time processing. This enables manufacturers and industries in sectors like energy, transportation, and agriculture to collect actionable insights from their equipment, leading to improved performance, predictive maintenance, and enhanced operational efficiency.

Creative Micro Systems: Redefining Industrial IoT Gateways

Creative Micro Systems has established itself as a leading provider of Industrial IoT Gateway solutions. The company’s focus is on creating high-performance, secure, and scalable solutions that address the unique demands of industrial environments. Their Industrial IoT Gateways are engineered to support a variety of communication protocols and are designed for rugged, real-time operation in mission-critical applications.

What sets Creative Micro Systems apart from the competition is their commitment to flexibility and reliability. Their gateways are compatible with numerous industrial protocols like Modbus, OPC-UA, MQTT, and REST, making them easily integrable into existing infrastructure. This is crucial for industries looking to modernize without disrupting their current systems.

Moreover, Creative Micro Systems ensures that its Industrial IoT Gateways are built to withstand harsh conditions commonly found in industrial settings, including extreme temperatures, humidity, and vibration. This ruggedness guarantees that the gateway continues to operate under challenging circumstances, ensuring that data collection and analysis remain uninterrupted.

Key Features of Creative Micro Systems' Industrial IoT Gateway

Real-Time Data Processing: The Industrial IoT Gateway by Creative Micro Systems processes data at the edge, reducing latency and ensuring that decision-makers have access to real-time insights. This is especially important for predictive maintenance, where timely intervention can prevent costly equipment breakdowns.

Connectivity Flexibility: Creative Micro Systems' gateways support a wide range of communication protocols, including serial, Ethernet, and wireless (Wi-Fi, LoRa, and 4G/5G). This flexibility makes it easy to integrate a diverse set of industrial devices, regardless of their communication standards.

Enhanced Security: Security is paramount in industrial environments, and Creative Micro Systems places a strong emphasis on data protection. Their gateways feature built-in encryption, secure VPN support, and firewall capabilities to safeguard sensitive data from potential cyber threats.

Scalability: Whether it's a small factory or a global network of industrial plants, Creative Micro Systems' gateways are designed to scale with business needs. Their solutions are adaptable to growing infrastructure, ensuring that companies can expand their IIoT networks without major disruptions.

Low Power Consumption: Industrial IoT devices often operate in remote or energy-sensitive environments. Creative Micro Systems ensures that their gateways are energy-efficient, reducing operational costs while maintaining continuous connectivity.

Cloud Integration: These gateways seamlessly integrate with popular cloud platforms like AWS, Microsoft Azure, and Google Cloud, enabling easy data aggregation, storage, and advanced analytics capabilities.

Why Choose Creative Micro Systems?

Creative Micro Systems stands out as a trusted partner for businesses looking to implement or upgrade their Industrial IoT Gateway solutions. Their products are not only robust and secure but also offer unmatched flexibility, scalability, and real-time data processing capabilities. By providing customized solutions that meet the specific needs of different industries, Creative Micro Systems helps companies unlock the full potential of their IIoT investments.

Benefits of Creative Micro Systems’ Industrial IoT Gateways

Operational Efficiency: Real-time monitoring and predictive analytics allow businesses to detect issues before they escalate, ensuring optimal performance and reducing downtime.

Cost Savings: By improving asset management and reducing the need for constant cloud processing, Creative Micro Systems' gateways contribute to lower operational costs.

Improved Decision-Making: With edge processing and faster access to relevant data, companies can make informed decisions faster, leading to improved overall productivity.

Seamless Integration: Whether modernizing legacy systems or integrating new IoT devices, Creative Micro Systems’ gateways offer plug-and-play compatibility with a wide variety of industrial networks.

Conclusion

In an era where industries are embracing digital transformation, Industrial IoT Gateways are essential for managing and leveraging the massive amounts of data generated by connected devices. Creative Micro Systems is at the forefront of this revolution, providing reliable, secure, and flexible solutions that enable companies to take full advantage of the IIoT. By choosing Creative Micro Systems, businesses can ensure seamless data flow, real-time decision-making, and greater operational efficiency—all critical components for success in today’s competitive industrial environment.

0 notes

Text

Power Up Your Automation: Discover Carlo Gavazzi’s Smart Industrial Solutions at Aeliya Marine

Solid State Relays (SSRs) Carlo Gavazzi solid state relays are built for high-speed, quiet, and dependable switching without moving parts. These SSRs are used in most applications involving frequent on/off switching, such as heating units, motor control, and industrial lighting.

Most Important Advantages:

No wear and tear of mechanical parts

High speed of switching

Resistant to vibration and shock

Sensors and Switches

From proximity sensors to photoelectric, capacitive, and inductive sensors, Carlo Gavazzi’s sensors are the eyes of today’s automation systems. They sense presence, position, level, and flow — all without touching anything.

Typical Applications:

Conveyor systems

Packaging machinery

Elevator controls

Marine engine monitoring

Energy Meters and Power Monitoring Devices

Energy efficiency starts with measurement. Carlo Gavazzi’s range of digital energy meters, power analyzers, and current transformers help facilities track energy use in real-time for improved energy management.

Why It Matters:

Reduces energy waste

Helps in meeting regulatory standards

Supports predictive maintenance strategies

Programmable Logic Controllers (PLCs)

Compact and easy to configure, Carlo Gavazzi’s PLCs are used to control machinery and processes in industries ranging from food processing to marine equipment automation. These units are built for flexibility and integration.

Features Include:

Remote monitoring capabilities

Multiple I/O options

Compatibility with Modbus, BACnet, and other protocols

Timers, Counters, and Monitoring Relays

For control panels and automated systems, Carlo Gavazzi timing and monitoring relays provide superior precision and reliability. They are must-have components to control operations, safeguard equipment, and minimize downtime.

Best Used For:

HVAC systems

Water treatment facilities

Motor protection and overload detection

Why Choose Carlo Gavazzi? The Power of Intelligent Automation

In a cutthroat industrial world, you require more than minimal automation. Carlo Gavazzi solutions are designed to enable enterprises to expand their operations with better, more interconnected solutions. The following is why they stand out:

Modular Design for Seamless Integration

The majority of Carlo Gavazzi products are modular, i.e., easily installed, replaceable, or expandable. From retrofitting an existing panel to designing a completely new system, integration is seamless and future-proof.

IoT and Industry 4.0 Ready

The world is moving towards smart factories and networked infrastructure, and Carlo Gavazzi is bang in the middle of it. Most of their energy meters, PLCs, and controllers offer communication through IoT-capable protocols such as Modbus, BACnet, and MQTT.

Global Compliance and Standards

All Carlo Gavazzi products are CE-marked and certified for sale in international markets. They comply with international EMC, safety, and performance standards and are ideal for use in critical applications in the energy, marine, and industrial industries.

Why Purchase Carlo Gavazzi from Aeliya Marine?

At Aeliya Marine, we’re committed to helping our customers find the right automation components at the right price — fast and reliably. Here’s why we’re the preferred supplier for Carlo Gavazzi parts:

Authenticity Guaranteed

Every Carlo Gavazzi component sold on Aeliya Marine is 100% genuine, sourced directly or through trusted distribution channels. No counterfeit parts — only original products that meet strict performance standards.

Fast Worldwide Shipping

No matter if you’re in Europe, Asia, the Middle East, or North America, we ship worldwide with safe packaging and quick logistics. We know how important timing is in industrial upkeep and project launch.

Expert Advice

Don’t know what sensor or relay is compatible with your system? Our technical support staff is a click or a call away. We will assist you in selecting the best component considering your specifications and operational objectives.

Large Inventory

We stock a broad range of Carlo Gavazzi components, from older models through to the newest designs. That translates into short lead times and faster turnaround for your company.

Industries That Use Carlo Gavazzi Solutions

The universality and durability of Carlo Gavazzi automated products make them a superior option in a wide range of industries:

Marine and Shipbuilding

Reliable electrical components are vital on ships, where downtime can be costly and dangerous. Carlo Gavazzi’s sensors, relays, and controllers are used in marine engine rooms, navigation systems, and cargo management.

Industrial Manufacturing

In factory automation, timing and precision are everything. Carlo Gavazzi’s smart sensors, PLCs, and monitoring relays help improve process control, reduce waste, and enable predictive maintenance strategies.

Agriculture and Irrigation

Smart irrigation relies on weatherproof and smart automation. Weatherproof sensors and timers from Carlo Gavazzi optimize the use of water and crop yield.

Smart Buildings

From HVAC controllers to energy meters, Carlo Gavazzi makes building automation smarter with lower energy bills, increased safety, and greater comfort.

Energy and Utilities

Their power monitoring and control products are utilized to maximize energy generation, distribution, and usage — essential for green energy initiatives as well as conventional power grids.

How to Shop the Carlo Gavazzi Collection on Aeliya Marine

We’ve made it simple to locate just what you’re looking for. Go to our Carlo Gavazzi vendor page here: https://aeliyamarine.com/collections/vendors?q=Carlo%20Gavazzi

There, you can:

Search by product name or part number

Filter by product type or category

View detailed specs and product photos

Add to cart or request a bulk quote

Whether you’re ordering a single replacement relay or equipping an entire system, our website is your one-stop destination for Carlo Gavazzi automation products.

Conclusion: Let Smart Automation Lead the Way

With the constantly changing scenario of industrial and marine automation, success is found in using the best parts and the appropriate vendors. Carlo Gavazzi provides smart, small, and durable solutions that drive the systems supporting today’s most important industries.

By joining forces with Aeliya Marine, you tap into a reliable inventory, informed guidance, and unparalleled customer support. Whether optimizing energy consumption, replacing a control panel, or designing a smart automation system from the ground up, our Carlo Gavazzi range has what you’re looking for.

Want to take your automation to the next level? Explore our complete Carlo Gavazzi range today → https://aeliyamarine.com/collections/vendors?q=Carlo%20Gavazzi

#industrial equipment#automation#industrialautomation#industrial spare parts#industrial and marine automation#marine automation#industrial automation#marine Automation#automationparts#marineparts#industrialparts#industrialmarineautomation#marineindustrialautomation#automationindustrial#automationmarine#marineautomationparts#industrialautomationparts#partsautomation#partsmarine

0 notes

Text

Understanding Modbus: The Universal Protocol for Industrial Communication

Modbus is a widely used communication protocol in industrial automation and control systems. Originally developed by Modicon (now Schneider Electric) in 1979, it remains one of the most popular protocols for connecting electronic devices and exchanging data in supervisory control and data acquisition (SCADA) systems, programmable logic controllers (PLCs), and various automation applications.

How Modbus Works

Modbus operates as a master-slave (or client-server) protocol, where a master device initiates communication, and one or more slave devices respond. It is simple, reliable, and efficient, making it a preferred choice for industrial communication. The protocol is used to transmit data over serial lines (RS-232, RS-485) or via Ethernet networks (Modbus TCP/IP).

Types of Modbus Protocols

Modbus RTU (Remote Terminal Unit): A binary protocol using compact messages with cyclic redundancy check (CRC) error checking. It is ideal for real-time communication.

Modbus ASCII: Similar to RTU but uses ASCII characters, making it more readable but less efficient.

Modbus TCP/IP: Allows Modbus communication over Ethernet networks using TCP/IP protocols, making it suitable for modern industrial networks.

Key Features of Modbus

Open and Vendor-Neutral: Modbus is an open standard, meaning any manufacturer can implement it without licensing fees.

Ease of Implementation: Simple message structure and minimal processing overhead.

Interoperability: Enables different devices and systems from various vendors to communicate seamlessly.

Scalability: Supports a range of devices, from small sensors to complex industrial control systems.

Robust Error Handling: Modbus RTU uses CRC for error detection, ensuring reliable data transfer.

Applications of Modbus

Industrial Automation: Connecting PLCs, sensors, actuators, and SCADA systems.

Energy Management: Monitoring and controlling power meters and generators.

Building Automation: HVAC control, lighting systems, and access control.

Water and Wastewater Management: Supervising pumps, valves, and treatment facilities.

Oil and Gas Industry: Remote monitoring of pipelines and drilling operations.

Challenges and Limitations

Despite its advantages, Modbus has some limitations:

Limited Data Security: Traditional Modbus lacks built-in encryption, making it vulnerable to cyber threats.

Slower Speed Compared to Modern Protocols: Serial-based Modbus RTU can be slower than newer protocols like Ethernet/IP or MQTT.

Single-Master Limitation: Classic Modbus architectures typically allow only one master device, restricting flexibility.

Future of Modbus

With the advent of Industry 4.0 and Industrial IoT (IIoT), Modbus continues to evolve. Modern adaptations like Modbus TCP/IP and secure Modbus variants are making it more compatible with smart factories and cloud-based systems. Its simplicity and reliability ensure that it remains relevant in industrial automation for years to come.

Conclusion

Modbus is an essential protocol in industrial communication, providing a simple yet powerful way to connect and control devices. Its widespread adoption, open standard nature, and continuous evolution make it a critical component in modern automation and control systems. As industries transition to smart manufacturing, Modbus will likely continue to play a significant role in bridging legacy systems with modern technologies.

0 notes

Text

Unlock Your Future in Smart Industries with IIoT!

The rapid advancement of technology has transformed industries across the globe, and the Industrial Internet of Things (IIoT) is at the forefront of this revolution. As industries move towards automation, smart factories, and real-time data-driven decision-making, IIoT is becoming an essential skill set for professionals.

Sharadha Skill Academy proudly presents an exclusive Industrial Internet of Things (IIoT) course designed to equip learners with hands-on experience, real-world applications, and industry-relevant knowledge. This comprehensive program will empower professionals and students alike to excel in the field of industrial automation and smart manufacturing.

Why Choose the IIoT Course at Sharadha Skill Academy?

✅ Practical Learning – Gain hands-on experience with IoT devices and industrial automation. ✅ Expert Guidance – Learn from industry professionals with years of experience. ✅ Career Advancement – Enhance your job prospects in the rapidly growing IoT sector. ✅ Affordable Fees – High-quality education at a reasonable cost. ✅ Limited Seats – Ensuring personalized attention and better learning outcomes.

Course Details

📅 Start Date: 3rd February 2025 ⏳ Duration: 5 Weeks 💰 Course Fee: ₹12,500

This course is meticulously designed to cover key aspects of IIoT, including:

Introduction to IIoT and Industry 4.0 – Understanding the evolution of industrial automation.

IoT Device Integration and Communication Protocols – Learning about MQTT, OPC UA, and Modbus.

Cloud Computing and Data Analytics in IIoT – Harnessing the power of cloud platforms.

Cybersecurity and Risk Management in Industrial Environments – Safeguarding industrial networks.

Who Should Enroll?

This course is perfect for:

Engineering students and graduates – Looking to build a strong foundation in IIoT.

Working professionals in manufacturing, IT, and automation sectors – Aiming for career growth and upskilling.

Entrepreneurs and business owners – Seeking to integrate IoT solutions in their operations.

What You Will Gain?

A deep understanding of IIoT concepts and their applications.

The ability to design and implement IIoT solutions for industries.

Hands-on experience with industry-grade IoT hardware and software.

Exposure to real-time industrial challenges and their solutions.

A certification that enhances your professional credentials.

The confidence to work in IIoT-related job roles and projects.

Enroll Now – Limited Seats Available!

Don’t miss out on this chance to upskill and future-proof your career in smart industries. With industries increasingly adopting IIoT for efficiency, sustainability, and automation, now is the perfect time to gain expertise in this transformative technology. Secure your seat today!

🌐 Website: sharadhaskillacademy.org 📞 Contact Us: +91 73977 88918 / 917 / 915 📍 Location: Sharadha Skill Academy, KG Garden City, Commercial Building 3rd Floor, Vedapatti, Via Nagarajapuram to Perur Road, Coimbatore – 641007, TN

Invest in your future – learn IIoT and take your career to the next level with Sharadha Skill Academy!

#IIoT#IndustrialAutomation#SmartIndustries#IoT#Industry40#Automation#Technology#SkillDevelopment#CareerGrowth#SharadhaSkillAcademy#TechTraining#CyberSecurity#CloudComputing#PredictiveMaintenance#SCADA#PLC#EdgeComputing#AI#MachineLearning#DataAnalytics#SmartManufacturing#TechInnovation#FutureSkills#HandsOnTraining#ProfessionalCertification#IndustrialRevolution#IoTSolutions#Engineering#Entrepreneurship#IndustrialEngineers

0 notes

Text

Vehicle Gateway: The Bridge to Intelligent Connected Vehicles

In the era of Internet of Things (IoT), Vehicle Gateway has emerged as a key technology. It acts as a bridge, enabling seamless communication between vehicles and the external world.

What is a Vehicle Gateway?

A Vehicle Gateway is a device that integrates multiple communication technologies, such as 4G/5G, Wi-Fi, and Ethernet. It allows vehicles to connect to the internet and exchange data with cloud platforms, other vehicles, and infrastructure.

Why Do We Need Vehicle Gateways?

Introducing the SV900: A Cutting-Edge Vehicle Gateway

Key Features of the SV900

Dual 5G or 5G+4G connectivity for redundancy and reliability

Optional Wi-Fi support with speeds up to 1774Mbps (Wi-Fi 6)

Multiple Ethernet ports for wired connectivity

Rugged design with IP40 protection and wide operating temperature range

Supports various VPN protocols and industrial protocols like MQTT and Modbus

Integrated with Star-Cloud platform for remote management

Empowering the Future of Connected Vehicles

The SV900 Vehicle Gateway enables a wide range of IoT applications in the automotive industry. From fleet management to autonomous driving, it provides the critical link between vehicles and the digital world. With its robust features and reliable performance, the SV900 is a top choice for building intelligent connected vehicle solutions.Vehicle Gateway technology is driving the evolution of smart transportation. As a leader in this field, the SV900 is well-positioned to accelerate the adoption of connected vehicles and shape the future of mobility.

1 note

·

View note

Text

IoT gateways play a crucial role in smart technology ecosystems by aggregating and processing data from various devices, ensuring seamless communication and interoperability.

#RS 485 IoT Gateway Solutions#Industrial IoT Gateway Solutions#industrial iot gateway devices#IOT gateway devices#IIoT gateway devices#MQTT IoT gateway#iot gateway manufacturers#Top IoT gateway companies#IoT gateway company#iot gateway solutions#modbus gateway#rs485 gateway#rs485 protocol#modbus rs485#modbus communication protocol#rs485 iot gateway#modbus protocol#iot gateway

0 notes

Text

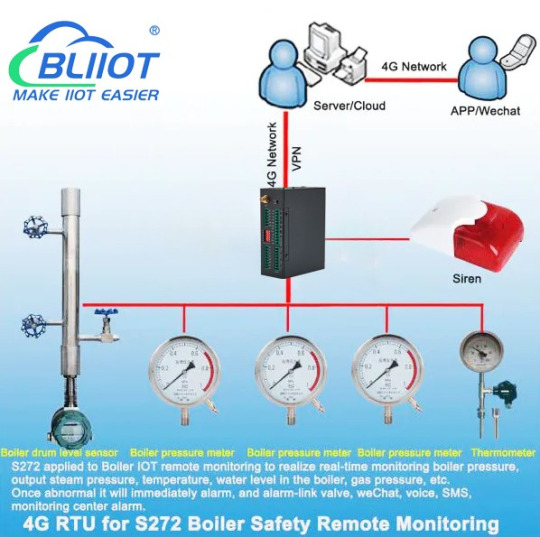

BLIIoT SMS/4G Remote Monitoring Gateway S275 Used in Boiler Monitoring

Foreword

Boilers are important equipment in industry and residential life. They provide hot water, steam and heat energy, but they also need to be closely monitored to ensure their safety and efficiency. BLIIoT SMS/4G Remote Monitoring Gateway S275 provides an intelligent solution for boiler monitoring to monitor the operating status of the boiler system such as air pressure, temperature, liquid level, and water leakage.

Boiler Monitoring Needs

In boiler monitoring applications, we usually need to monitor the following parameters:

Air Pressure Monitoring: Maintaining proper air pressure is critical to proper boiler operation.

Temperature monitoring: Monitoring the temperature of your boiler can help prevent overheating or cooling.

Liquid level monitoring: Ensure the water level is within a safe range to avoid low water levels or overflows.

Water leakage detection: timely detect water leakage to avoid equipment damage and reduce energy waste.

Flue gas emission monitoring: Monitor flue gas emissions to ensure the environmental protection of the boiler.

Alarm notification: promptly notify operation and maintenance personnel or management personnel to deal with emergencies or abnormal situations.

Application of Remote Monitoring Gateway S275 in Boiler Monitoring

Data Collection and Monitoring

Using Remote Monitoring Gateway S275, we can easily configure the sensor to monitor various parameters of the boiler system in real time. By connecting analog and digital sensors, the device can collect data on air pressure, temperature, liquid level, water leakage, smoke emissions, etc. and save it in an internal database for subsequent analysis and reporting. This helps identify potential problems early and take appropriate action.

Alarms and Notifications

Remote Monitoring Gateway S275 has a powerful alarm function, and users can set alarm thresholds based on monitoring data. Once these thresholds are exceeded or dropped, the device triggers an alarm notification to notify relevant personnel. This real-time alert can help take quick action to reduce potential risks.

Remote Control

Keeping your boiler system safe and reliable isn't just about monitoring, it's also about real-time control. The relay output of Remote Monitoring Gateway S275 can be used to control pumps, valves, fans and other equipment, shutting down or starting them remotely when needed. This remote control capability helps reduce risk and improve operational efficiency.

Data Transfer and Cloud Integration

Remote Monitoring Gateway S275 supports multiple communication protocols such as SMS, Modbus, MQTT, etc. to transmit data to the cloud platform. This means you can integrate boiler monitoring data into cloud solutions, enabling remote access, data visualization and analysis. In addition, the device is also compatible with multiple public cloud platforms such as Huawei Cloud and Alibaba Cloud, as well as users' private cloud platforms.

Safety

Data security is critical for boiler monitoring. Remote Monitoring Gateway S275 provides security measures for data transmission and storage, including data encryption and authentication. This helps ensure your boiler monitoring data is protected from unauthorized access and manipulation.

In Conclusion

Remote Monitoring Gateway S275 is a powerful terminal device that can be widely used in the field of boiler monitoring. It provides comprehensive data collection, monitoring, alarm and control functions, and supports multiple communication protocols and cloud platform integration to ensure the safety and reliability of the boiler system. Whether it is an industrial boiler, heating boiler or other type of boiler, Remote Monitoring Gateway S275 can provide an efficient solution for boiler monitoring.

More information about BLIIoT SMS/4G Remote Monitoring Gateway S275 : https://www.bliiot.com/m2m-rtu-p00175p1.html

0 notes

Text

Introduction to Messung BACD ECY-400 Series: Key Features and Benefits

The landscape of building automation is ever evolving. The need for scalable and customizable automation solutions is growing remarkably. Messung Building Automation & Controls Divisions has introduced the ECY-400 series controllers. These are made to meet the various demands of modern building management systems. This article takes a closer look into the key features and benefits of the ECY-400 series.

Purpose and Application of ECY-400 Series

The ECY-400 Series controllers are created to manage a wide range of building automation processes. These can be an air handling unit control system or a multi-zone application. Even boilers, pumps, and rooftop units can benefit from these controllers. You can use these for medium-sized equipment so as to bring a versatile solution to your complex building management needs. The ECY-400 Series supports BACnet/IP communications. These further have been listed as BACnet Building Controllers (B-BC). This unique solution can seamlessly integrate with your building management system. You can then enjoy precise control and monitoring.

Key Features of the ECY-400 Series

Here are the key features of the ECY-400 Series:

Portable Build

The portable build of ECY-400 series controllers sets them apart from other counterparts. You can install these flexibly into the current environments and spaces. You can even mount them either vertically or horizontally. This proves helpful if the space you have is limited and you have to make the most of it. Portability makes ECY-400 easy to integrate into many systems without any extensive programming or modification. The controller has inbuilt 12 UI and 12 UO.

Intuitive UI

You also get an optional full-color backlit display with a jog dial in the ECY-450 series controllers. This can give you direct access to a wide range of controller functions. The operation and configuration of the controller are thoroughly simplified with an intuitive user interface. Users of the controller can then easily navigate through differing settings and parameters. Moreover, the embedded web server helps with web-based application configuration. It also helps with a visualization interface. This can enhance the user experience with real-time data and control options.

Vast Networking Capabilities

Networking is an important aspect of a building automation system. ECY-400 Series is the perfect option for this. You get two Ethernet ports and an AUX port for configuring separate networks. If you are prioritizing isolated and fail-safe daisy-chaining applications, you can use the flexible networking options provided by these controllers. ECY-400 series is an adaptable solution that you are looking for to manage complex automation environments.

Software-Configurable IOs

You will never have to perform physical manipulation as long as you use the ECY-400 series software-configurable IOs. Such flexibility is important for easier communication and configuration. This way, the controller can work to meet every specific need of each building automation application. When you can easily configure the IOs through software, it is much easier to install the controllers into the existing environment. This reduces the time and effort you put into setting up the system.

Several Protocols

A wide range of communication protocols are supported in the ECY-400 series controllers. These include BACnet, MS/TP, and BACnet/SC. Additionally, it can support MODBUS, MBus, RTU, MQTT, and TCP. Multi-protocol systems are known to ensure ease of communication and authentication. You can even make the most of error detection across different devices within a building management system. Compatibility with various protocols helps this controller series enhance flexibility and interoperability experiences. This way, you can integrate new devices and expand your system further.

Benefits of the ECY-400 Series

Let us now learn the benefits of the ECY-400 Series:

Ease of Installation and Mounting

With the ECY-400 series, you get incomparable ease of installation. This is because of its compact design and flexible mounting options. It does not matter if you are trying to fit these controllers into an existing building automation system or are setting up a whole new one; the ECY-400 series is suitable for it all. These controllers integrate into all systems without the need for extensive modifications. You will spend much less time on installation and less money on other costs with these controllers.

Impressive User Experience Guarantee

Intuitive UI and embedded web servers are the building blocks of the ECY-400 series controllers. They even have software configurable IOs that can help with an impressive user experience. Users of these controllers have the option to configure, monitor, and control the system in a user-friendly interface. The learning curve in these controllers is thus much reduced. Instead, there is more scope for efficiency. User experience is further enhanced with an optional full-color display along with a jog dial.

Networking Across Multi-Protocol System

The multi-protocol system supported by ECY-400 series controllers is a way toward seamless networking. You can maintain connectivity with diverse systems with a building management setup. All multi-protocol environments can make the most of the ECY-400 series’ reliable communication and data exchange capabilities. With these controllers, you can always stay ahead with comprehensive control and monitoring of the entire building complex.

Conclusion

The ECY-400 series by Messung BACD brings forward a comprehensive solution. It works well for all modern building automation needs. Furthermore, it boasts a compact design with an intuitive interface. These powerful controllers are made to add efficiency to whatever space they are installed in.

0 notes

Text

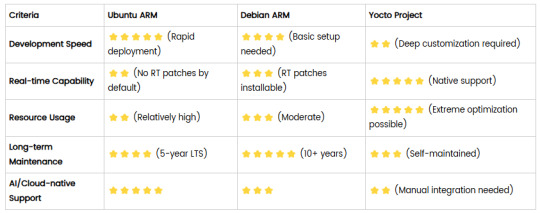

Comparison of Ubuntu, Debian, and Yocto for IIoT and Edge Computing

In industrial IoT (IIoT) and edge computing scenarios, Ubuntu, Debian, and Yocto Project each have unique advantages. Below is a detailed comparison and recommendations for these three systems:

1. Ubuntu (ARM)

Advantages

Ready-to-use: Provides official ARM images (e.g., Ubuntu Server 22.04 LTS) supporting hardware like Raspberry Pi and NVIDIA Jetson, requiring no complex configuration.

Cloud-native support: Built-in tools like MicroK8s, Docker, and Kubernetes, ideal for edge-cloud collaboration.

Long-term support (LTS): 5 years of security updates, meeting industrial stability requirements.

Rich software ecosystem: Access to AI/ML tools (e.g., TensorFlow Lite) and databases (e.g., PostgreSQL ARM-optimized) via APT and Snap Store.

Use Cases

Rapid prototyping: Quick deployment of Python/Node.js applications on edge gateways.

AI edge inference: Running computer vision models (e.g., ROS 2 + Ubuntu) on Jetson devices.

Lightweight K8s clusters: Edge nodes managed by MicroK8s.

Limitations

Higher resource usage (minimum ~512MB RAM), unsuitable for ultra-low-power devices.

2. Debian (ARM)

Advantages

Exceptional stability: Packages undergo rigorous testing, ideal for 24/7 industrial operation.

Lightweight: Minimal installation requires only 128MB RAM; GUI-free versions available.

Long-term support: Up to 10+ years of security updates via Debian LTS (with commercial support).

Hardware compatibility: Supports older or niche ARM chips (e.g., TI Sitara series).

Use Cases

Industrial controllers: PLCs, HMIs, and other devices requiring deterministic responses.

Network edge devices: Firewalls, protocol gateways (e.g., Modbus-to-MQTT).

Critical systems (medical/transport): Compliance with IEC 62304/DO-178C certifications.

Limitations

Older software versions (e.g., default GCC version); newer features require backports.

3. Yocto Project

Advantages

Full customization: Tailor everything from kernel to user space, generating minimal images (<50MB possible).

Real-time extensions: Supports Xenomai/Preempt-RT patches for μs-level latency.

Cross-platform portability: Single recipe set adapts to multiple hardware platforms (e.g., NXP i.MX6 → i.MX8).

Security design: Built-in industrial-grade features like SELinux and dm-verity.

Use Cases

Custom industrial devices: Requires specific kernel configurations or proprietary drivers (e.g., CAN-FD bus support).

High real-time systems: Robotic motion control, CNC machines.

Resource-constrained terminals: Sensor nodes running lightweight stacks (e.g., Zephyr+FreeRTOS hybrid deployment).

Limitations

Steep learning curve (BitBake syntax required); longer development cycles.

4. Comparison Summary

5. Selection Recommendations

Choose Ubuntu ARM: For rapid deployment of edge AI applications (e.g., vision detection on Jetson) or deep integration with public clouds (e.g., AWS IoT Greengrass).

Choose Debian ARM: For mission-critical industrial equipment (e.g., substation monitoring) where stability outweighs feature novelty.

Choose Yocto Project: For custom hardware development (e.g., proprietary industrial boards) or strict real-time/safety certification (e.g., ISO 13849) requirements.

6. Hybrid Architecture Example

Smart factory edge node:

Real-time control layer: RTOS built with Yocto (controlling robotic arms)

Data processing layer: Debian running OPC UA servers

Cloud connectivity layer: Ubuntu Server managing K8s edge clusters

Combining these systems based on specific needs can maximize the efficiency of IIoT edge computing.

0 notes